If the monthly BE (energy) scale has drifted by more than 0.2 eV then you most definitely need to ask the service engineer to adjust the electronics that control the energy scale to return to acceptable BEs for the 3 calibrants. The drift can be in total length of the energy scale or it can be just the high BE end.

Energy Scales of all chemical analysis instruments need to be checked monthly, or weekly, to determine if the experimental results are reliable or not. For each instrument, the tool manager should make a BE run chart which over time will indicate if the electronics are stable and reliable. If the trend chart shows a dip after a few weeks or months, then the tool manager needs to find a solution to this problem so users do not receive or publish erroneous BEs.

Energy Scales of chemical analysis instruments need reference energy points, Calibration Energies, that are used to define reliable, reproducible Energy values that are measured routinely (monthly) to check if the energy scale of an instrument has drifted or changed. This is a crucial check which ensures accurate energy measurements of the BEs obtained XPS spectra collected from all kinds of materials.

Ion Etch each Calibration Metal (calibrant) just before

Measuring the Calibration BE of each Metal

Simple measuring BEs of Cu 2p3, Au 4f7 or Ag 3d5 signals is NOT calibration of BE energy scale. This is just step one. Checking BE Spectra tell us how much the instrument has drifted away from the desired calibrated BE values (ISO values). The instrument service engineer can adjust to correct for such drift.

To be able to collect data with accurate, well-calibrated values we must “VERIFY” that freshly measured calibration BEs are very close to the “standard” calibration BEs. For XPS the ultimate uncertainty is defined to be +/-0.02 eV. Sadly very few instruments are calibrated to match this level.

XRI Guideline for Measuring Calibration Spectra BEs before Adjusting XPS BE Scale

- Load all 3 Calibration Metals onto the same sample mount. Place them so they are 1 cm apart from each other.

- If the Copper or Silver are heavily oxidized, use a single edge razor blade to scrape an area clean enough to be measured.

- Load them into your main analysis chamber.

- Ion etch each sample just before you actually measure chemical state spectra from them.

- Gold needs only a little ion etching usually.

- Silver needs to be ion etched for about 1 minute using 1-2 kV Argon ions.

- Copper needs to be ion etched for about 2 minutes using 1-2 kV Argon ions.

- After you peak-fit the chemical state spectra for Cu 2p3, Ag 3d5, and Au 4f7, then you are ready to adjust your instrument Reference Energy Voltages.

- Each software allows us to adjust Reference Energy Voltages using different methods. Talk to your Service man for more details if you do not know what voltages or energy settings to adjust.

- Be sure to add the just obtained BE values to your Trend Run chart next to the date of the verification

Calibration (reference) energies, developed by an international team of XPS experts, were published in 2001 by the International Standards Organization (ISO) Technical Committee (TC/201) for Surface Chemical Analysis as ISO document #15472 (titled: Surface chemical analysis – X-ray photoelectron spectrometers –Calibration of energy scales).

The ISO BE calibration energies for a monochromatic Al-k-α1 source for:

These ISO values are reported with ±0.02 eV uncertainty, and they represent the first international effort to standardize the calibration energies used to calibrate the energy scales of XPS instruments worldwide.

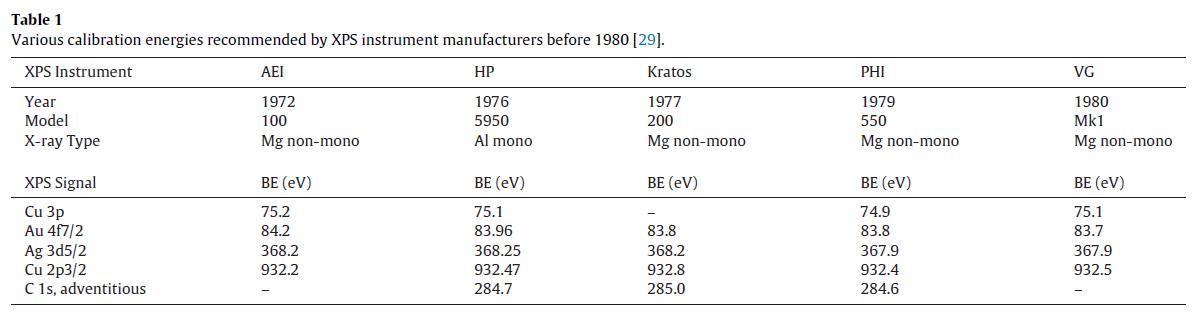

Table 1 shows the large variation in BE Calibration Values that were previously promoted by many XPS instrument makers. This large variation is BE Calibration values caused many scientists and researchers to publish BEs from research materials that can not be reproduced by other researchers or scientists. These large variations caused large variations in the BEs published in the literature, many handbooks and the NIST SRD20 database.

As a result we need to be careful when we use literature BE values from insulators and conductors before 2010. We need to make fresh BEs from pure materials.

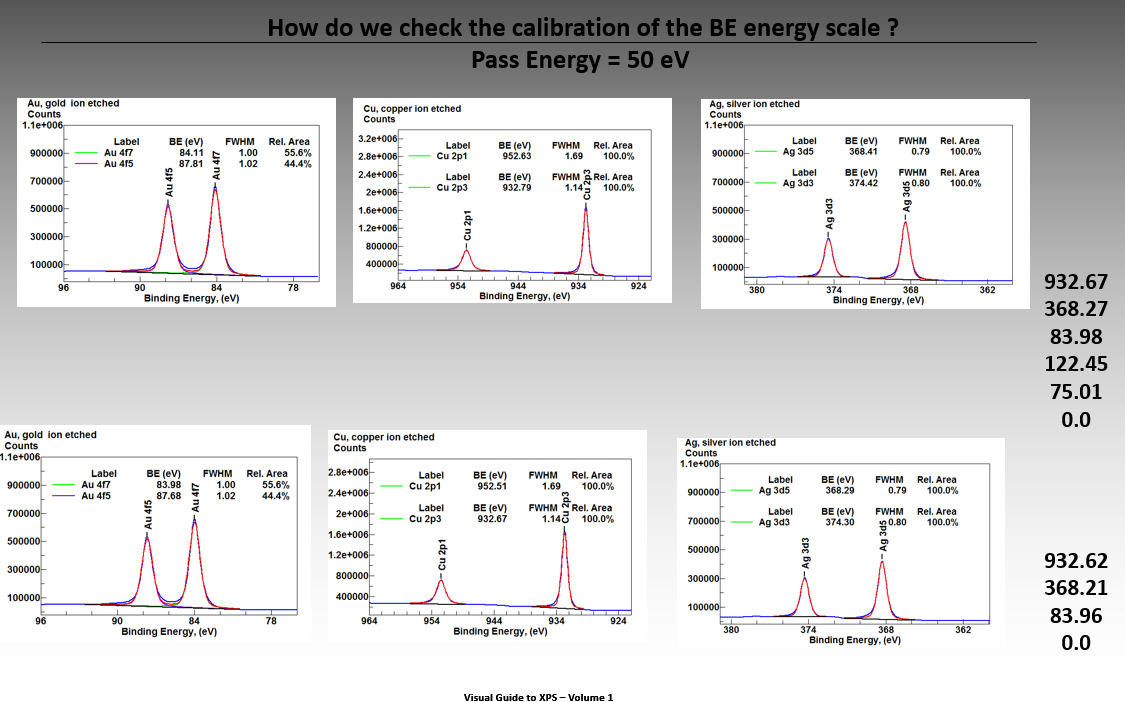

How do we check the Calibration of our BE energy scale?

NOTE: Checking (Measuring) BEs of Cu 2p3, Au 4f7 or Ag 3d5 signals is NOT calibration of BE energy scale. It is only step one of Calibrating your BE energy scale. The Checking BE Spectra tell us how much the instrument has drifted from the desired BE values (ISO values).

- Load all 3 Calibration Metals onto the same sample mount. Place them so they are 1 cm apart from each other.

- If the Copper or Silver are heavily oxidized, use a single edge razor blade to scrape an area clean enough to be measured.

- Load them into your main analysis chamber.

- Ion etch each sample just before you actually measure chemical state spectra from them.

- Gold needs only a little ion etching usually.

- Silver needs to be ion etched for about 1 minute using 1-2 kV Argon ions.

- Copper needs to be ion etched for about 2 minutes using 1-2 kV Argon ions.

- After you peak-fit the chemical state spectra for Cu 2p3, Ag 3d5, and Au 4f7, then you are ready to adjust your instrument Reference Energy Voltages.

- Each software allows us to adjust Reference Energy Voltages using different methods. Talk to your Service man for more details if you do not know what voltages or energy settings to adjust.

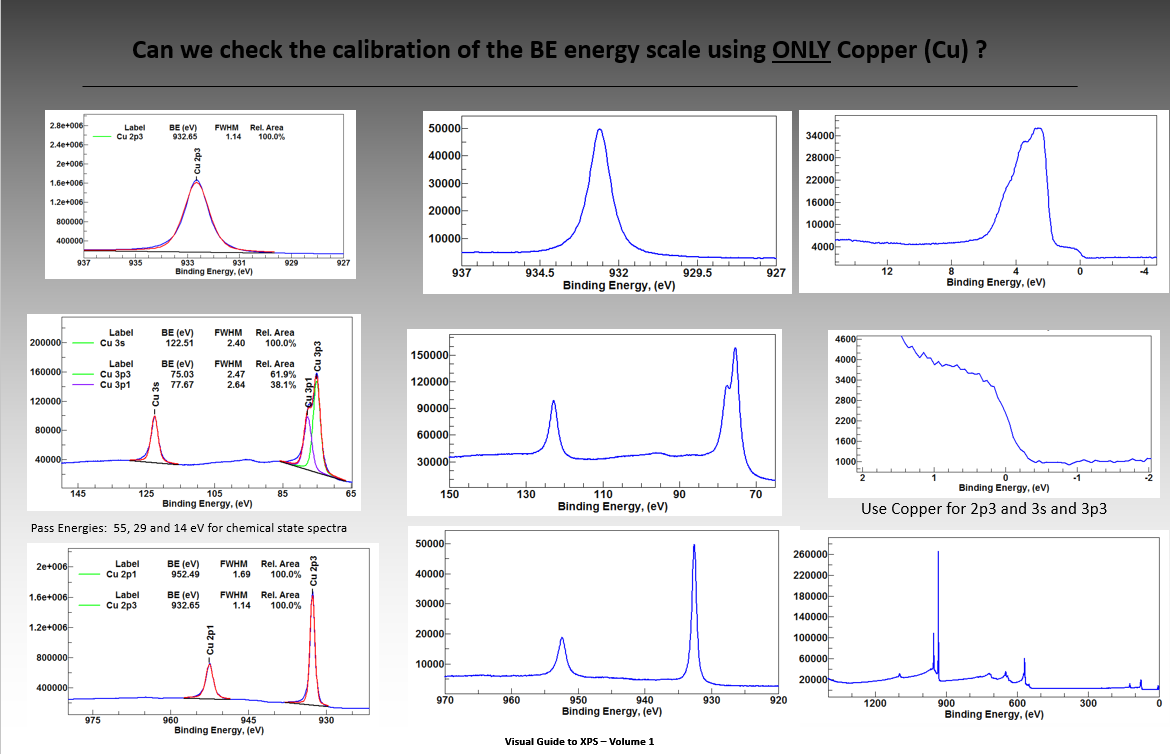

Can we Calibrate the Energy Scale using ONLY Copper (Cu) ? Should we? Is it reliable? Is it easy?

YES !

Menu Links to The XPS Library website

- BE Calibration – Rules

- BE Calibration Values

- BE Calibration – History

- BE Reliability Problem

- Calibration Checks – Validation of BE Scale

- Calibration Metals

- Deposited Gold

- Fermi Edge

- International BE Calibration – IXIR

- Ion Etching – Ag, Au, Cu

- ISO BE Standards

- Publishing XPS Data

- Separation in Calibration Energies (SCE) Values

- X-ray Energies